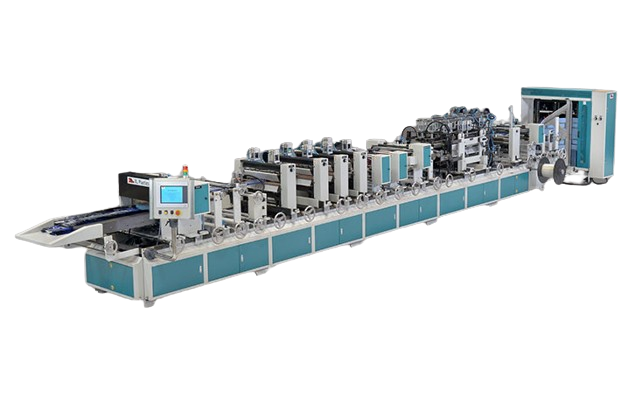

Introduction: In the dynamic realm of packaging, adaptability and versatility stand as key pillars of success. Among the arsenal of cutting-edge machinery, the Bag Making Machine emerges as a linchpin, revolutionizing the packaging landscape. This article delves into the indispensable role of these machines, particularly in crafting flat bottom pouches, stand-up pouches, ziplock bags, and even specialized applications like diaper packaging.

1. Crafting Flat Bottom Pouches: Flat bottom pouches have become synonymous with modern packaging aesthetics and functionality. The Bag Making Machine's ability to precisely shape and seal these pouches ensures a sleek, uniform appearance while optimizing shelf space. This format not only enhances branding opportunities for companies but also provides consumers with a visually appealing and easily stackable packaging solution.

2. Elevating Stand-Up Pouches: Stand-up pouches have become a consumer favorite due to their convenience and eye-catching presentation. Bag Making Machines equipped for this style play a pivotal role in creating durable, leak-proof seals, maintaining the pouch's upright position. This feature is crucial for products ranging from snacks to liquid detergents, where stability and spill prevention are paramount.

3. Convenience with Ziplock Bags: Ziplock bags have become synonymous with convenience, allowing consumers to reseal packages for freshness. Bag Making Machines that incorporate ziplock capabilities not only provide this sought-after feature but also ensure airtight seals, preserving product quality. The ease of use associated with ziplock closures enhances the overall user experience and contributes to customer satisfaction.

4. Specialized Diaper Packaging: In the realm of specialized packaging, such as diaper packaging, the Bag Making Machine takes center stage. Its ability to accommodate various materials, including those with barrier properties, ensures that diapers remain hygienically sealed until use. The precision in creating custom shapes and sizes caters to the specific requirements of the diaper industry, reflecting the adaptability of these machines.

5. Myler Bags Packaging: In the realm of specialized packaging, such as myler bags packaging, the Bag Making Machine takes center stage. Its ability to accommodate various materials, including those with barrier properties. The precision in creating custom shapes and sizes caters to the specific requirements of the bag making industry, reflecting the adaptability of these machines.

6. Specialized Mailing Bags Packaging: In the realm of specialized packaging, such as mailing bags packaging, the Bag Making Machine takes center stage. Its ability to accommodate various materials, including those with barrier properties, ensures that mailing remains sealed when use with the help of inclusive tape. The precision in creating custom shapes and sizes caters to the specific requirements of the mailing industry, reflecting the adaptability of these machines.

Conclusion: The Bag Making Machine, with its capacity to produce flat bottom pouches, stand-up pouches, ziplock bags, and cater to specialized needs like diaper packaging, is a linchpin in the modern packaging landscape. Its versatility not only meets current consumer demands for functionality and aesthetics but also anticipates future trends. As packaging continues to be a crucial element in product presentation and preservation, investing in advanced Bag Making Machines becomes not just a choice but a strategic imperative for companies aspiring to lead in the competitive world of packaging.